|

One of the less-common items you will need is a set of pickle forks (see picture below). These are used to seperate the ball

joint from the the spindle. You can find them at auto parts stores (often times on the

"cheap tool table" or at places like Harbor Freight). You'll also need a good size (weight) hammer to use the pickle

forks effectivly. We used a 3lb "drilling" hammer (kind of small, hand-held sledge hammer) and it worked well because

it has some weight to it and a large striking face. If you don't have this type of hammer (or some other heavy, large-face

hammer) your might want to get one. They make the job a lot easier and less likely that you'll accidently hit your hand,

cuss and have to get your wife to drive you to the emergency room, etc.

Replacement parts...

You will also need lower ball joints. There are variety of opinions on which brand(s)

of parts to use and whether or not to use OEM (Ford) parts. There are definitely a large number of knowledgable repair

people who strongly believe that many OEM Ford suspension parts are better-made and last longer than many if not most

of the aftermarket replacement parts. For example, many mechanics who service Crown Victoria police and fleet

vehicles often prefer OEM Ford parts becuase in their experience they just last longer and hold up better.

Having said that, Ford does not actually make lower ball joints (or tie rods, etc.) they source them from companies

like TRW, Moog, Dana, and others. These same companies market their parts through your local auto parts stores.

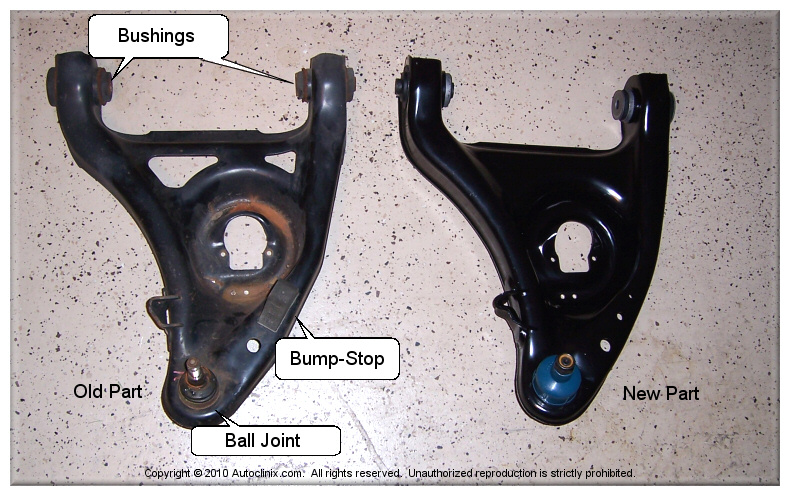

We chose to use some aftermarket lower control arm aseemblies from MevoTech which looked good and fit nicely. Our only complaints about

these parts is that the ball joints on these pre-assebled units did not have grease fittings or provisions for them and the new parts also did

not include new rubber bump-stops; we had to remove and re-use the ones from the orignal control-arms.

Looking Underneath...

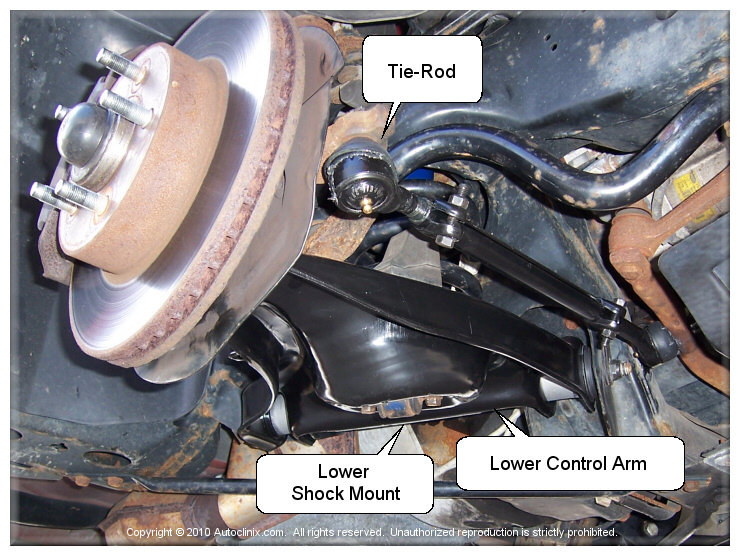

The picture below shows some of the suspension components you'll see when you get under your car.

|